Australian researchers are testing fabric samples from gown manufacturers to find out how to best keep healthcare workers safe from COVID-19.

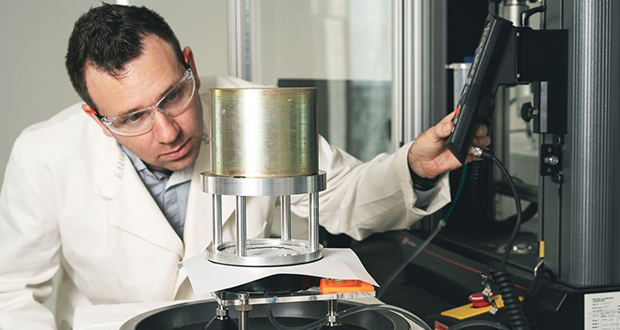

The Medical Device Research Institute (MDRI) team, based at Flinders University, is testing the fabrics for resistance to bacteria, viruses and fluids.

And in a separate project, Flinders experts are testing 3D printed mask seals moulded to the faces of individual healthcare workers to reduce the risks caused by poor fit.

Currently, gowns need to be sent overseas for testing but Flinders has established an Australian-based facility to fast-track the process for homegrown manufacturers.

Pathogens will also be grown on site to create an environment where gowns can be tested against viruses and bacteria.

MDRI director Professor Karen Reynolds said: “The idea is that manufacturers can bring their gowns here, we can run the tests and they can move forward with production, meanwhile hospital services can be confident their staff are properly protected.”

Meanwhile, cardiologist Associate Professor Anand Ganesan and fellow Flinders researcher Darius Chapman are working to prevent gaps between a standard N95 grade face mask and a healthcare worker’s face.

To do so, the duo will use a mobile phone app to scan the 3D geometry and coordinates of an individual’s face before printing out a bespoke seal.

Ganesan said: “The human face is so variable and there’s different shapes and sizes for everyone so a generic one size fits all mask won’t capture everyone, so we’ve set about trying to limit the leak from these masks.”

“We’ve also seen images of our colleagues, particularly in other parts of the world, with bruises and pressure sores on their nose and cheeks from the force of continually wearing masks with the straps pulled tightly to try to protect themselves.”

Do you have an idea for a story?Email [email protected]

Aged Care Insite Australia's number one aged care news source

Aged Care Insite Australia's number one aged care news source